OUR SERVICES

CURRENT PROJECTS

PLASTIC > Plastic production facility

Stroke data from plastic injection machines was collected with our data collection devices, providing precise timing information. Through the Tamveri Software, production was tracked based on work orders, customers, and products. Machine operators were tracked using RFID card scanning through our data collection devices. Downtime data was collected by entering the reasons for machine downtime through the devices. Quality control personnel were enabled to perform quality checks and barcode scans using their mobile phones. Entry of scrap and production data was also facilitated.

TEXTILE > Fabric Dyehouse

The integration of Tamveri Software with the ERP program within the business was established. Data collection devices on the business machines were used to scan RFID cards, enabling the entry of start-to-finish process information on a per-person basis. Data on electricity, water, and natural gas consumption from all machines were collected through our data collection devices, allowing for reporting based on date and work order. Live dashboard monitoring screens were created.

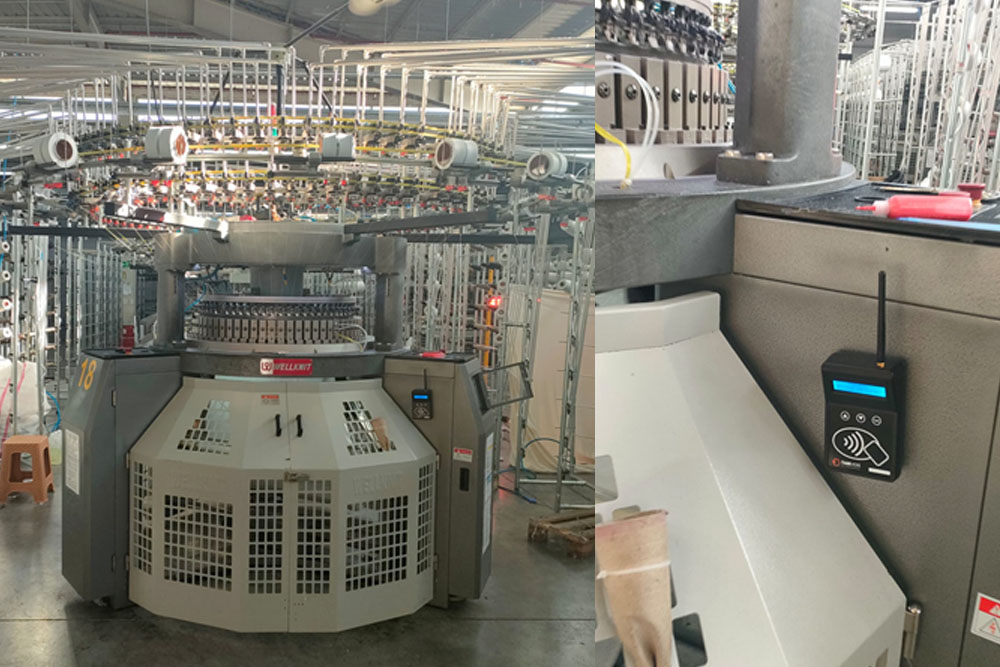

TEXTILE > Knitting Facility

Integration of Tamveri Software with the ERP program within the business was established. Data collection devices on all knitting machines in the facility were used to collect data on machine cycle time. Based on the cycle time data, the machine downtime and operating times were evaluated, productivity was measured, and reporting was carried out. Live dashboard monitoring screens were created.

TEXTILE > Ribbon Weaving Facility

İşletmedeki tüm kurdela dokuma makinaları üzerindeki veri toplama cihazlarımızdan makinaların tur verisinin toplanması sağlandı. Tur verisine istinaden makinaların duruş ve çalışma süreleri değerlendirilerek verimlilik ölçüldü, raporlanması sağlandı, canlı dashboard izleme ekranları oluşturuldu.

PACKAGING > Printing Facility

Production meters from all machines in the facility were collected using our data collection devices, and productivity was measured. Integration of Tamveri Software with the ERP program within the business was established to enable tracking of production on a work order basis. Special sensors were installed on the printing machines to collect data on functions such as coil cutting, material slipping, and error entries. Users were provided with access to the data via tablets, and print receipts by using Bluetooth printers. Data reporting was implemented, and live dashboard monitoring screens were created.

YOUR BUSINESS

What can be done specifically for your business?

How can we digitize your data?

What integration possibilities exist?

How can we facilitate easy tracking of your business?

Let's evaluate together, let's plan projects tailored to your needs, let's conduct free demo application studies at critical points.

We can find tailor-made solutions to your problems.

Give us a call, let's have a discussion, and we can also visit you.

How can we digitize your data?

What integration possibilities exist?

How can we facilitate easy tracking of your business?

Let's evaluate together, let's plan projects tailored to your needs, let's conduct free demo application studies at critical points.

We can find tailor-made solutions to your problems.

Give us a call, let's have a discussion, and we can also visit you.

Contact information